The Secret Of Info About How Do You Connect Cable Wires

Connecting Cable Wires

1. Understanding the Basics

So, you're staring at a bunch of wires and wondering how to make them play nice together? Don't worry, we've all been there! Connecting cable wires isn't rocket science, but it does require a bit of know-how to avoid short circuits and, you know, turning your lights off permanently. The main point here is that "connect cable wires" is a verb phrase, describing an action. And like any action, doing it right matters.

Before you even think about twisting anything together, identify the type of wires you're dealing with. Are they copper? Aluminum? Is it electrical wiring or something else entirely (like coax cable for your TV)? This makes a huge difference! Mixing metals can lead to corrosion and a poor connection. Safety first, always! Turn off the power at the breaker before you start tinkering. We're aiming for illumination, not electrocution!

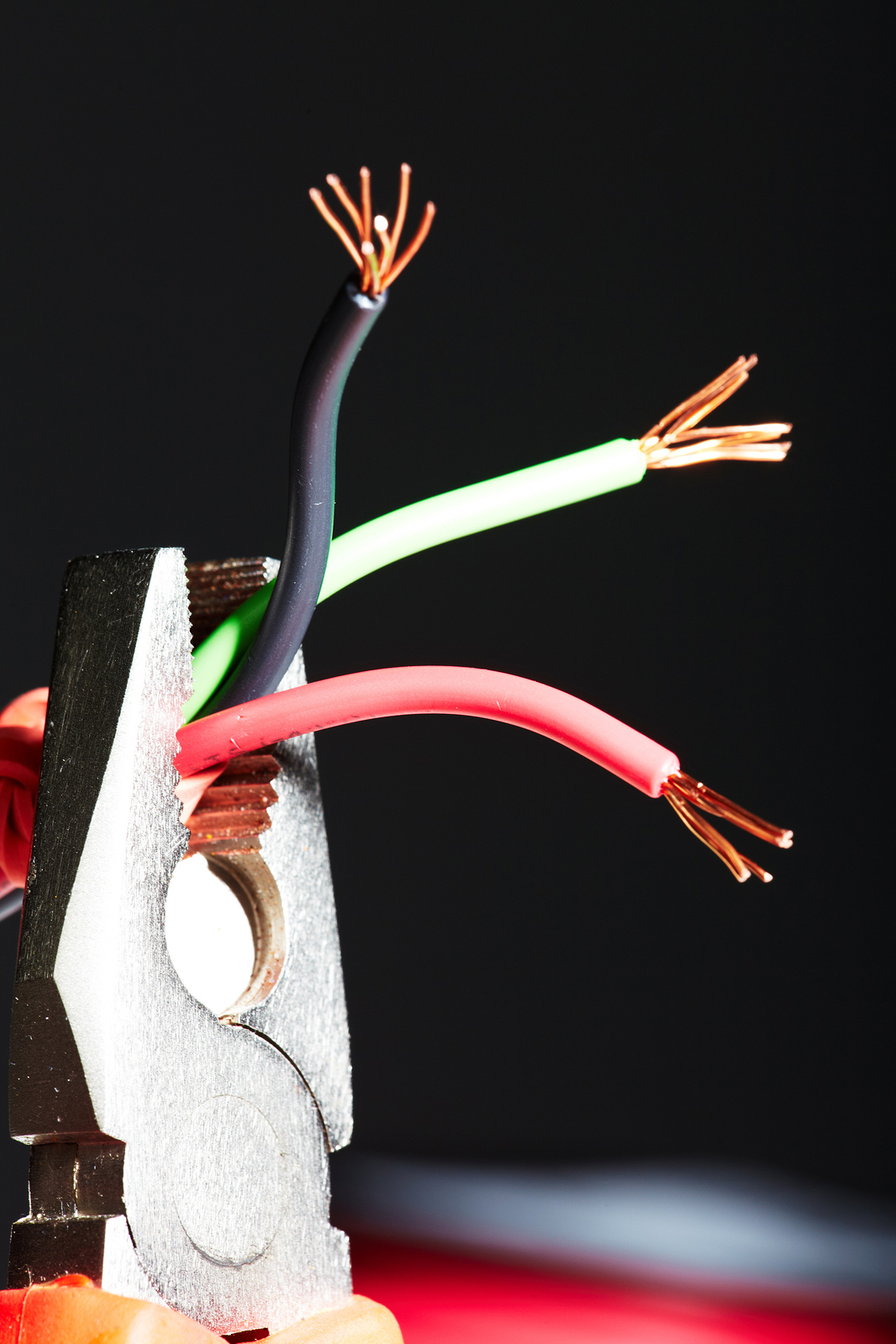

Next, you'll need the right tools. A wire stripper is essential for removing the insulation without damaging the wire itself. Pliers come in handy for twisting and securing connections. And, of course, some kind of connector — wire nuts, crimp connectors, or even solder, depending on the application. Having the right tools will make the whole process smoother and safer.

Think of it like baking. You wouldn't try to make a cake without a mixing bowl and an oven, would you? Similarly, attempting to connect wires without the proper tools is a recipe for frustration (and potentially a very dark house).

Choosing Your Weapon

2. Wire Nuts, Crimp Connectors, and Beyond

Alright, let's talk about the various ways to actually connect cable wires. The most common method, especially in residential electrical work, is using wire nuts. These little plastic caps twist onto the exposed ends of the wires, providing insulation and a secure connection. They're easy to use and relatively inexpensive, making them a popular choice.

Crimp connectors are another option. These involve inserting the wires into a metal sleeve and then crimping it tightly with a special tool. They're often used for automotive wiring and other applications where a strong, vibration-resistant connection is needed. They can be a bit more fiddly than wire nuts, but they offer a more permanent connection.

Then there's soldering. This involves melting solder (a metal alloy) over the exposed wires to create a solid, conductive bond. Soldering requires a bit more skill and equipment (a soldering iron, solder, and flux), but it provides a very reliable connection. It's often used in electronics and other applications where a low-resistance connection is critical.

Which method you choose depends on the specific application, your skill level, and your budget. Wire nuts are great for general electrical work, crimp connectors are good for automotive wiring, and soldering is best for electronics. Each has its pros and cons, so weigh your options carefully.

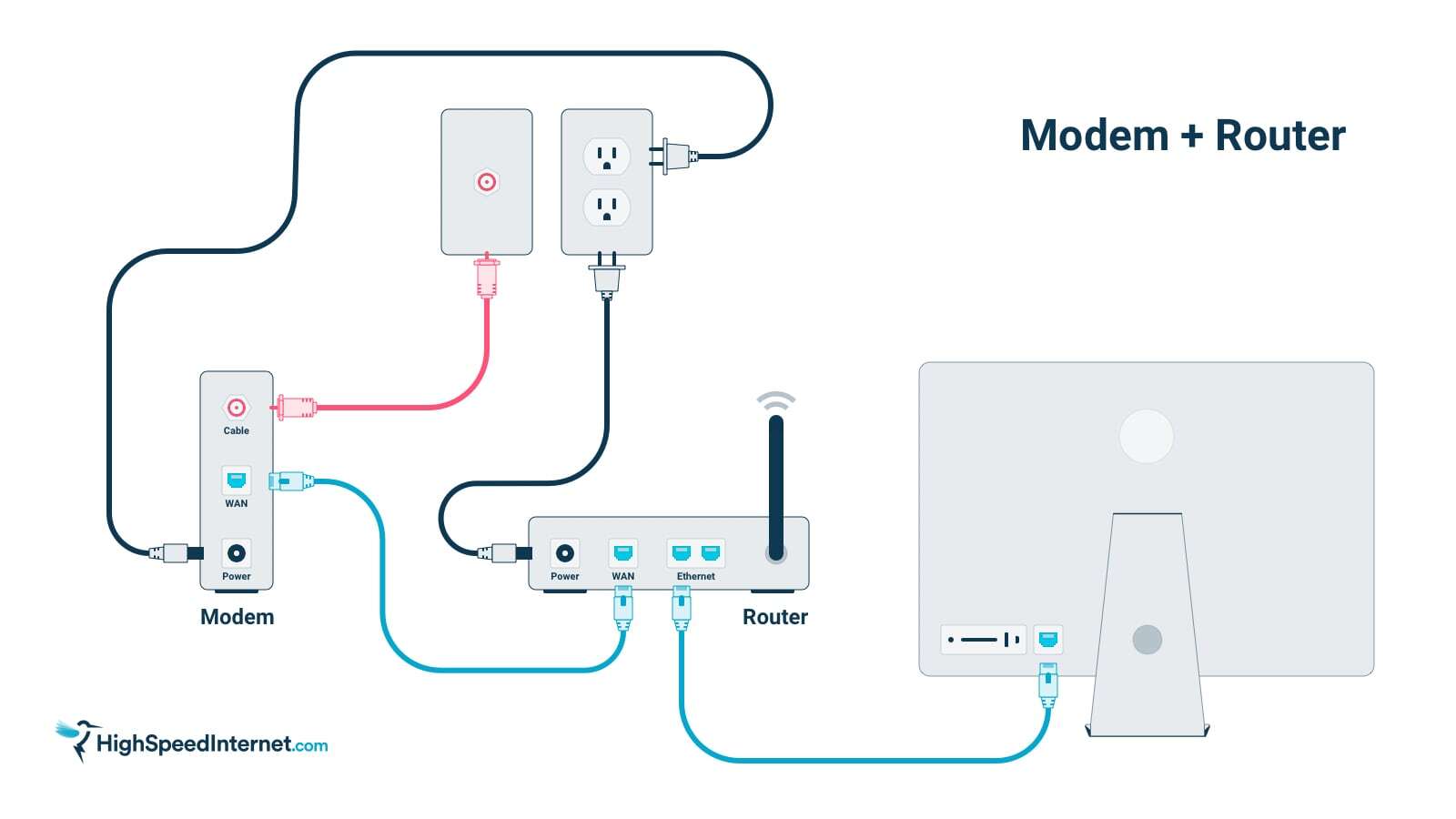

Wireing Cable Configuration Network Lan Ne

The Art of the Twist

3. Getting It Right So You Don't Have to Do It Again

No matter which method you choose, the key to a good connection is a solid mechanical bond between the wires. With wire nuts, this means twisting the wires together tightly before screwing on the nut. Strip about inch of insulation from each wire. Hold the stripped ends parallel to each other, with the ends aligned. Twist the wires together clockwise, using pliers if necessary, until you have a tight spiral of bare wire.

Make sure the twist is strong enough to hold the wires together without the wire nut. The wire nut is there to provide insulation and extra security, not to hold the entire connection together. A loose connection can lead to arcing, overheating, and even a fire. Not ideal!

When using crimp connectors, be sure to use the correct size connector for the gauge of wire you're using. The connector should fit snugly around the wires. Use a crimping tool to compress the connector tightly around the wires, creating a permanent bond. A good crimp should be strong enough to withstand significant pulling force.

With soldering, clean the wires thoroughly before applying solder. Use flux to help the solder flow smoothly and create a strong bond. Heat the wires with the soldering iron, then apply the solder. Allow the solder to flow around the wires and create a shiny, smooth connection. Let it cool before moving the wires. Be sure to wear eye protection when soldering, as hot solder can splatter.

How To Tie Two Wires Together At Murray Blog

Safety First (Seriously!)

4. Avoiding Electrocution and Other Unpleasant Surprises

I can't stress this enough: safety is paramount when working with electrical wiring. Always turn off the power at the breaker before you start working. Test the wires with a non-contact voltage tester to make sure they're dead. Wear safety glasses to protect your eyes from debris. And use insulated tools to avoid accidental shocks.

If you're not comfortable working with electrical wiring, don't be afraid to call a qualified electrician. It's better to be safe than sorry. Electrical work can be dangerous, and it's not worth risking your safety to save a few bucks. Plus, incorrect wiring can create fire hazards that could endanger your home and family.

Never work in damp or wet conditions. Water is an excellent conductor of electricity, and it can significantly increase your risk of electrocution. Make sure the area you're working in is dry and well-ventilated. If you're working outdoors, wait for a dry day.

And finally, always double-check your work before turning the power back on. Make sure all connections are secure and properly insulated. Look for any signs of damage or wear. If you're not sure about something, ask a qualified electrician for help. Peace of mind is worth its weight in gold!

Joining Electrical Wires

Troubleshooting Common Problems

5. When Things Go Wrong (and They Sometimes Do)

Even with the best preparation, things can sometimes go wrong when connecting cable wires. A common problem is loose connections. This can cause flickering lights, intermittent power outages, and even overheating. If you suspect a loose connection, turn off the power and carefully inspect the wiring. Tighten any loose connections or replace damaged connectors.

Another problem is short circuits. This occurs when a bare wire comes into contact with another bare wire or a grounded metal surface. Short circuits can cause breakers to trip and can even start fires. If you suspect a short circuit, turn off the power immediately and inspect the wiring for damage. Repair any damaged insulation or replace faulty components.

Sometimes, the wires may not be making a good connection even though they appear to be tightly connected. This can be due to corrosion or oxidation on the wire surfaces. Clean the wires with a wire brush or sandpaper to remove any corrosion or oxidation. Apply a small amount of antioxidant compound to the wires before connecting them.

If you're still having problems after troubleshooting, it's best to call a qualified electrician. They have the experience and equipment to diagnose and repair complex electrical problems safely and effectively. Remember, your safety is paramount!

How To Connect Wires Electrical Outlet

FAQ

6. Because We Know You Have Them!

Q: Can I connect different gauges of wire together?A: Yes, but with caution! You should generally avoid connecting significantly different gauges of wire, as this can create a bottleneck in the circuit and cause overheating. If you must connect different gauges, use a connector that's rated for both sizes and make sure the smaller wire is protected by an appropriately sized circuit breaker.

Q: What happens if I don't strip enough insulation off the wire?A: If you don't strip enough insulation, the bare wire won't make good contact, leading to a weak or intermittent connection. This can cause flickering lights, power outages, and overheating. Always strip enough insulation to ensure a solid connection.

Q: Can I reuse wire nuts?A: It's generally not recommended to reuse wire nuts. Over time, they can become damaged or lose their grip. It's best to use new wire nuts for each connection to ensure a secure and reliable bond. They're pretty cheap, so why risk it?

Q: Is it okay to wrap electrical tape around wire nuts as extra safety?A: While it might seem like a good idea, properly installed wire nuts don't actually need electrical tape for safety. However, in some situations, like damp locations or areas with vibration, wrapping the wire nut with electrical tape can provide an extra layer of protection against moisture and loosening. Make sure the wire nut is correctly sized and tightly secured first. The tape is just a bonus layer, not a substitute for a good connection.