Fabulous Tips About What Are The Advantages And Disadvantages Of A Closed-loop System

Overview Of Control System Ppt Download

Understanding Closed-Loop Systems

1. What Exactly Is a Closed-Loop System, Anyway?

Ever wondered how your cruise control keeps your car at a steady speed, even when going uphill? Or how your home thermostat manages to keep the temperature just right, no matter how cold it gets outside? The answer, in many cases, is a closed-loop system! Essentially, its a self-regulating marvel that uses feedback to maintain a desired state.

Think of it like this: you're baking a cake. You follow the recipe (that's your initial input), but you don't just blindly shove it in the oven and hope for the best. You check it occasionally. If it's browning too fast, you might lower the oven temperature or tent it with foil. That's feedback in action! A closed-loop system does something similar, constantly monitoring its output and making adjustments to keep things on track. It is a system where the output is fed back into the system as an input, allowing for continuous monitoring and correction. The "closed-loop system" noun at here refers to the system which is controlled by feedback.

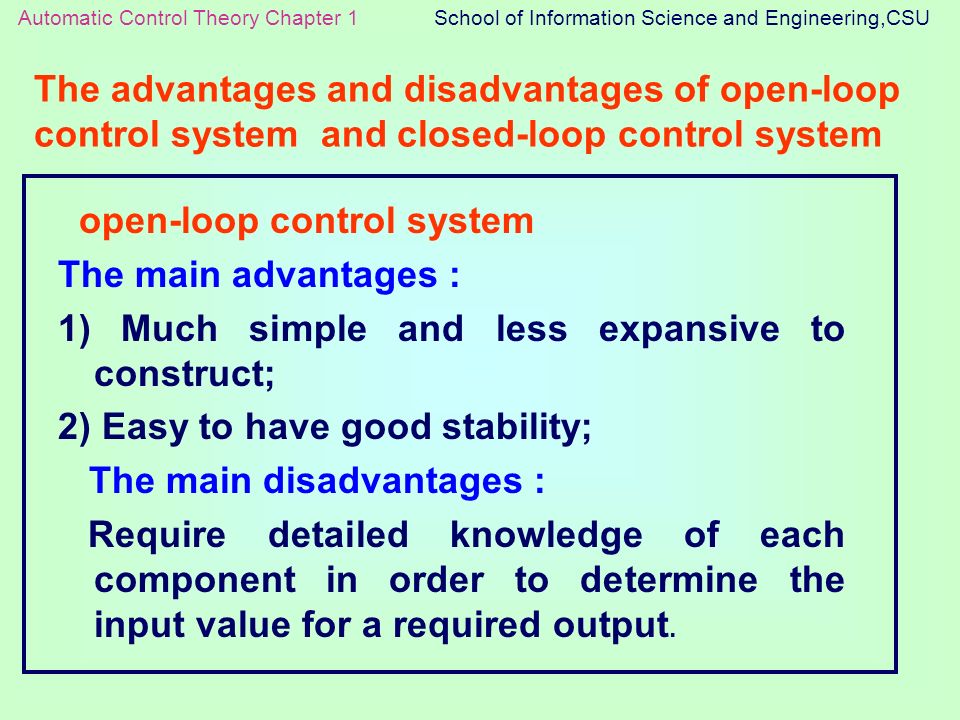

Unlike an open-loop system, which just churns along regardless of what's actually happening (like a toaster that runs for a set time, regardless of whether your bread is actually toasted), a closed-loop system is aware of its own performance. It's like having a built-in quality control department constantly working to ensure everything is just right. This awareness is crucial for maintaining stability and accuracy.

So, in a nutshell, a closed-loop system is a smart, self-correcting mechanism that relies on feedback to achieve and maintain a desired result. Now that weve got the basics down, lets explore the good and the not-so-good aspects of these systems.

Automatic Control Theory Ppt Video Online Download

The Upsides

2. Precision and Accuracy

One of the biggest advantages of a "closed-loop system" is its ability to deliver exceptional precision and accuracy. Because it's constantly monitoring its output and making adjustments, it can compensate for disturbances and variations that would throw an open-loop system completely off course. Its like having an incredibly skilled archer who can adjust their aim based on the wind and distance to consistently hit the bullseye.

Imagine a chemical plant where precise temperature control is essential for a specific reaction. A closed-loop system can maintain that temperature within very tight tolerances, ensuring consistent product quality. Without this feedback mechanism, even minor fluctuations could lead to unwanted side reactions and a ruined batch. That would be a costly mistake!

Think about your car's engine control unit (ECU). It uses a "closed-loop system" to manage the air-fuel mixture, ignition timing, and other critical parameters. By monitoring sensors that measure engine speed, temperature, and oxygen levels, the ECU can make real-time adjustments to optimize performance and fuel efficiency. The result? A smoother, more responsive, and more economical driving experience.

This level of accuracy translates into several benefits, including reduced waste, improved efficiency, and higher product quality. Whether its in manufacturing, aerospace, or healthcare, the precision offered by closed-loop systems is often essential for achieving optimal results.

3. Adaptability and Robustness

Another key advantage of a "closed-loop system" is its ability to adapt to changing conditions. Unlike open-loop systems, which are pre-programmed with a fixed set of instructions, closed-loop systems can adjust their behavior in response to disturbances and uncertainties. This adaptability makes them much more robust and reliable in real-world applications.

Consider an automated guided vehicle (AGV) in a warehouse. As it navigates through the aisles, it might encounter obstacles, changes in floor surface, or variations in load weight. A closed-loop control system allows the AGV to adjust its speed, steering, and power output to maintain its desired trajectory, even in the face of these challenges. Its like a self-driving car that can handle unexpected road conditions.

Furthermore, "closed-loop system" can often tolerate a wider range of input signals and operating conditions than their open-loop counterparts. This robustness is particularly valuable in environments where conditions are unpredictable or constantly changing. For example, a climate control system in a greenhouse can adjust the temperature, humidity, and ventilation based on real-time weather data, ensuring optimal growing conditions for the plants, regardless of the external environment.

This adaptability and robustness ultimately lead to greater reliability and reduced downtime. Because the system can compensate for unexpected events, its less likely to fail or require manual intervention. This translates into cost savings and improved operational efficiency. Think of it as an investment that pays off in the long run through increased resilience and performance.

4. Automation and Efficiency

The inherent feedback mechanism of a "closed-loop system" makes it ideal for automation. Because the system can continuously monitor its own performance and make adjustments as needed, it can operate with minimal human intervention. This leads to increased efficiency and reduced labor costs.

Think about a modern manufacturing plant. Robots equipped with closed-loop control systems can perform repetitive tasks with incredible precision and speed, without requiring constant supervision. These robots can assemble products, weld components, and paint surfaces, all while maintaining consistent quality and minimizing errors. This allows human workers to focus on more complex and creative tasks.

Moreover, a "closed-loop system" can be used to optimize processes in real-time. By analyzing data from sensors and adjusting control parameters accordingly, the system can maximize throughput, minimize energy consumption, and reduce waste. For example, a smart grid can use closed-loop control to balance electricity supply and demand, optimizing energy distribution and preventing blackouts.

This level of automation not only improves efficiency but also enhances safety. By taking humans out of hazardous or repetitive tasks, closed-loop systems can reduce the risk of accidents and injuries. Its a win-win situation: increased productivity and a safer working environment.

Open Loop Control System Vs Closed

The Downsides

5. Complexity and Cost

While the advantages of a "closed-loop system" are compelling, it's important to acknowledge the downsides. One of the main drawbacks is their increased complexity compared to open-loop systems. This complexity translates into higher initial costs and more effort required for design, implementation, and maintenance.

Because "closed-loop system" relies on sensors, controllers, and actuators to monitor and adjust its output, it requires more sophisticated hardware and software. Designing and integrating these components can be a challenging task, requiring specialized expertise. Furthermore, the system must be carefully tuned to ensure stability and optimal performance. This often involves extensive testing and calibration.

The increased complexity also means that a "closed-loop system" are more prone to failures and require more frequent maintenance. Sensors can drift out of calibration, controllers can malfunction, and actuators can wear out over time. Diagnosing and repairing these problems can be time-consuming and expensive, especially if specialized equipment or expertise is required.

However, it's important to note that the long-term benefits of a "closed-loop system" often outweigh the initial costs. While the upfront investment may be higher, the increased efficiency, accuracy, and reliability can lead to significant cost savings over the lifetime of the system. It's a classic case of "you get what you pay for."

6. Stability Issues

The very feedback mechanism that makes a "closed-loop system" so effective can also be a source of instability. If the feedback loop is not properly designed and tuned, it can lead to oscillations, overshooting, or even outright instability. Imagine a thermostat that keeps overcorrecting, causing the temperature to swing wildly between too hot and too cold. Not exactly comfortable!

The risk of instability is particularly high in systems with long time delays or complex dynamics. These delays can cause the controller to react too slowly or too aggressively, leading to oscillations. Furthermore, nonlinearities in the system can make it difficult to predict its behavior and design a stable control system. A "closed-loop system" requires careful analysis and design to ensure that the feedback loop is stable under all operating conditions.

To mitigate these risks, engineers often use sophisticated control algorithms and techniques, such as proportional-integral-derivative (PID) control, model predictive control, and adaptive control. These algorithms can help to stabilize the system and optimize its performance. However, they also add to the complexity of the system and require specialized knowledge to implement effectively.

Despite the potential for instability, a well-designed and tuned "closed-loop system" is generally more stable and reliable than an open-loop system. The key is to carefully consider the dynamics of the system and choose appropriate control algorithms and parameters. Its all about finding the right balance between responsiveness and stability.

7. Potential for Sensor Errors

A "closed-loop system" is only as good as the information it receives from its sensors. If the sensors are inaccurate or unreliable, the control system will make incorrect adjustments, leading to poor performance or even system failure. Its the "garbage in, garbage out" principle in action.

Sensors can be affected by a variety of factors, including noise, drift, calibration errors, and environmental conditions. These errors can lead to inaccurate readings, which can throw off the entire control system. For example, a faulty temperature sensor in a chemical reactor could cause the temperature to deviate from its desired setpoint, leading to unwanted side reactions or even an explosion.

To minimize the impact of sensor errors, it's important to choose high-quality sensors and calibrate them regularly. Redundant sensors can also be used to provide backup in case of sensor failure. Furthermore, signal processing techniques can be used to filter out noise and correct for drift.

Even with these precautions, it's important to be aware of the potential for sensor errors and to design the control system to be robust against them. This might involve using fault-tolerant control algorithms or incorporating diagnostics to detect and isolate sensor failures. The goal is to ensure that the system can continue to operate safely and effectively, even in the presence of imperfect sensor data.

ClosedLoopControlSystemAdvantagesDrawbacks Advantages And

FAQ

8. Q

A: Imagine controlling the water temperature in your shower. An open-loop system would be like setting the hot and cold taps to a fixed position without checking the water temperature. A closed-loop system would be like constantly adjusting the taps based on how the water feels on your skin. The key difference is the feedback loop: closed-loop systems use feedback to self-correct, while open-loop systems don't.

9. Q

A: Not necessarily! While closed-loop systems offer superior accuracy and adaptability, they are also more complex and expensive. Open-loop systems can be perfectly adequate for simple applications where precision isn't critical, and conditions are predictable. Think of a simple light switch; it's an open-loop system that works just fine for turning a light on or off.

10. Q

A: You're surrounded by them! Cruise control in your car, thermostats in your home, autopilots in airplanes, and even the automatic flushing mechanism in some toilets are all examples of closed-loop systems in action. They are everywhere to make life easier and better for us.

11. Q

A: Consider these factors: How critical is accuracy? How much do conditions vary? What's your budget? If accuracy is paramount, conditions are unpredictable, and you're willing to invest in complexity, a closed-loop system is probably the way to go. Otherwise, an open-loop system might suffice. Weigh the pros and cons carefully.