Fun Tips About How To Find Bill Of Materials In SAP

Unlocking the Secrets of Your SAP Bill of Materials (BOM)

1. What's a BOM and Why Should I Care?

Okay, let's say you're building a super-cool gadget. You need a list of every single nut, bolt, wire, and widget that goes into making that gadget, right? That list is essentially your Bill of Materials, or BOM. In SAP, the BOM is your master recipe for creating products. Its not just a list; it's a structured hierarchy detailing components, quantities, and relationships. Understanding how to find this vital information within SAP is key to efficient manufacturing, procurement, and even cost analysis. Think of it as the DNA blueprint for everything your company makes — pretty important stuff!

Without a clear understanding of your BOMs, you might end up with mismatched parts, production delays, or even products that just plain don't work. Nobody wants that headache! A well-maintained BOM ensures accuracy, consistency, and ultimately, a smoother operation. So, knowing how to navigate the SAP landscape to locate and understand these documents is a critical skill. So, let's get started!

Consider the BOM as the ultimate shopping list for your production team. Need 100 red widgets, 50 blue gizmos, and a sprinkle of magic dust? The BOM tells your purchasing department exactly what to order and how much. This level of detail is crucial for preventing stockouts and ensuring that your production line never grinds to a halt.

Beyond just the component list, a BOM in SAP provides context. It outlines the sequence of assembly, the specific machines used, and even the person responsible for each step. This level of transparency not only streamlines production but also makes troubleshooting a breeze. Imagine trying to fix a complicated machine without knowing its inner workings; the BOM is your user manual for manufacturing success.

Sap Bill Of Material

Hunting Down Your BOM

2. Getting Your Hands Dirty with SAP Transactions

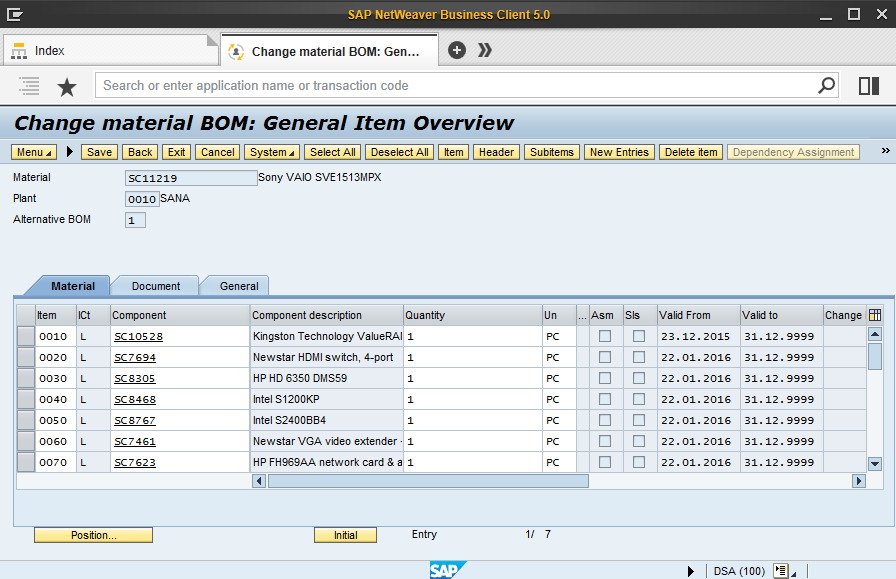

Alright, time to dive into the SAP system itself! Finding your BOM typically involves a few key transaction codes. The most common one you'll encounter is CS03 (Display Material BOM). Think of it as your primary search tool for viewing existing BOMs. Just pop in the material number and plant, and BAM! You're presented with the component list. But SAP's complexity doesn't end there.

Another handy transaction is CS11 (Display Where-Used List). This one is a game-changer when you need to know which products a specific component is used in. Imagine you're phasing out a particular part. Using CS11, you can quickly identify all the BOMs that include that part, making the transition much easier. Consider this a 'reverse lookup' tool that saves you countless hours of manual searching.

And lets not forget transaction CS15 (Find Direct Where-Used List for Component). This one's a bit more surgical — it pinpoints only the BOMs where the component is directly used, avoiding indirect connections. This is useful when you need immediate answers about where a specific component is essential.

Navigating the SAP GUI can feel like exploring a maze at times. But fear not! Practice makes perfect. Start with the basics CS03, CS11, and CS15 – and gradually explore other related transactions as you become more comfortable. Remember, there's no shame in using SAP's help function (usually accessed by pressing F1). It's there to guide you through the process and explain the nuances of each transaction.

Bill Of Materials Item No Essential For Inventory Management In SAP

Decoding the BOM Structure

3. Breaking Down the BOM Jargon

Once you've found your BOM, you'll be greeted with a screen full of information. Understanding what all those fields mean is crucial. You'll see things like item numbers, component quantities, unit of measure, and various control keys. Don't be intimidated! Each piece of information plays a vital role in the overall picture.

The item number indicates the sequence in which the components are assembled. The component quantity tells you how many of each part are needed for one unit of the finished product. The unit of measure specifies whether you need pieces, kilograms, liters, or some other measurement. The control key dictates how the component is used in the manufacturing process, whether its stocked, directly produced, or purchased from an external vendor.

Pay close attention to the validity dates on each component. A BOM can have multiple versions active at the same time, each valid for a specific period. Make sure you're looking at the correct version for the production order you're working on. Otherwise, you might end up ordering the wrong parts or using an outdated assembly process.

Learning the BOM structure is like learning a new language. Start with the basic vocabulary item numbers, quantities, units of measure and gradually expand your knowledge as you gain experience. Don't be afraid to ask your colleagues for help or consult SAP documentation. With a little practice, you'll be fluent in BOM-speak in no time!

Beyond the Basics

4. Level Up Your BOM Game

So, you've mastered the basics of finding and understanding BOMs. Now it's time to explore some advanced techniques. One such technique is using engineering change management (ECM) to track changes to the BOM over time. This ensures that you always have a complete history of every modification, who made it, and why.

Another useful technique is to use BOM comparisons to identify differences between two versions of the same BOM. This can be helpful when troubleshooting production problems or trying to understand the impact of a design change. SAP provides tools to highlight discrepancies, making it easier to pinpoint the root cause of issues.

Furthermore, explore configurable materials. These are complex products that can be customized to meet specific customer requirements. The BOM for a configurable material is dynamic, meaning that the components included in the final product depend on the options selected by the customer. Understanding how to navigate configurable BOMs is essential for companies that offer highly customizable products.

Finally, consider integrating your BOM with other SAP modules, such as production planning (PP) and materials management (MM). This allows you to streamline your entire supply chain, from order placement to product delivery. By connecting your BOM to other business processes, you can improve efficiency, reduce costs, and enhance customer satisfaction. Now you're really becoming a BOM expert!

Spare Parts Items List In Sap Reviewmotors.co

Troubleshooting Common BOM Issues

5. When Things Go Wrong (and How to Fix Them)

Even with the best training and procedures, things can sometimes go wrong with your BOM. One common issue is missing or incorrect components. This can happen if the BOM wasn't properly updated after a design change or if someone accidentally deleted a component. Double-checking is always a good idea!

Another common problem is inconsistencies between the BOM and the actual production process. This can occur if the BOM is outdated or if the shop floor is using a different process than what's documented. Regular audits and communication between engineering and production are essential to prevent these discrepancies.

Sometimes, you might encounter BOMs that are too complex or poorly structured. This can make it difficult to understand and manage the product. In these cases, it's best to simplify the BOM by breaking it down into smaller, more manageable sub-assemblies. A well-structured BOM is easier to maintain and less prone to errors.

Ultimately, the key to troubleshooting BOM issues is to have a systematic approach. Start by gathering all the relevant information, such as the material number, production order, and any error messages. Then, use SAP's debugging tools to trace the problem back to its source. Don't be afraid to ask for help from your colleagues or SAP support if you get stuck. With a little persistence, you can resolve even the most complex BOM issues.

FAQ

6. Everything You Wanted to Know (But Were Afraid to Ask)

Q: How can I tell if a BOM is active?A: Check the validity dates! An active BOM has a validity period that includes the current date. Also, look for a status indicator that confirms the BOM is released for use.

Q: Can I create multiple BOMs for the same material?A: Absolutely! You can have multiple BOMs with different usages (e.g., production BOM, costing BOM) or different validity periods. Just make sure you're using the correct one for the task at hand.

Q: Is there a way to print a BOM?A: Yes! Within the CS03 transaction (or similar), you'll find a print function. You can also export the BOM data to a spreadsheet for further analysis and formatting.

Q: How do I update a BOM when a component changes?A: Use the Engineering Change Management (ECM) functionality in SAP. This allows you to track changes to the BOM and ensure that everyone is using the latest version. This is a critical step in maintaining BOM accuracy and consistency.